Cixi Feijie Bearing Co., Ltd.

Cixi Feijie Bearing Co., Ltd.

Cixi Feijie Bearing Co., Ltd.

Cixi Feijie Bearing Co., Ltd.

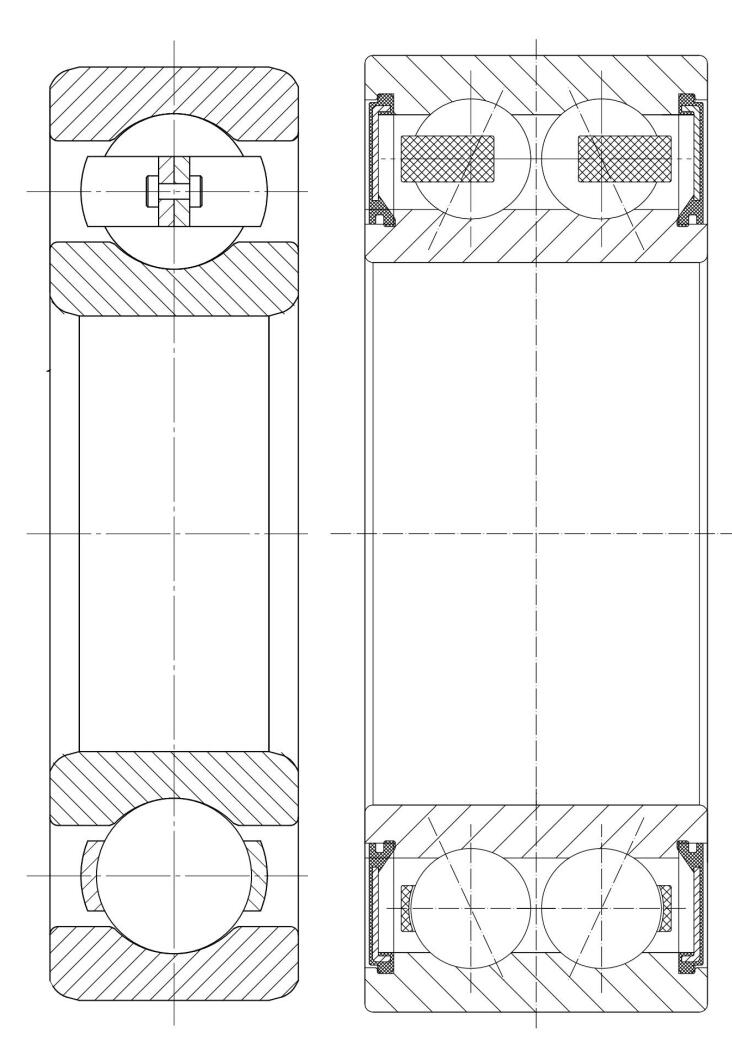

Roller bearings outer ring using outer ring wall thicker deep groove ball or double row angular contact ball bearing structure, the outer diameter surface of the roller has a linear, circular arc, V-shaped and tapered, etc., the outer diameter surface shape according to the use of the occasion design, used with the track surface. Using this outer ring, the rollers can roll directly on the raceway and can withstand heavy loads and shock loads. The bearings are of sealed construction and are grease filled to provide long term effective lubrication and the user can be lubricant free.

Feijie offers more than 200 different types of ball bearings for guideways (in bearing steel and stainless steel).

Deep groove balls with thick outer ring walls

Double row angular contact ball bearings

Can withstand heavy loads and shock loads.

Easy to use as no grease is required for grease lubrication.

Logistics conveyors, line conveyors, packaging machinery, printing machinery, forklifts, guide rails and other machinery

1Keeping the bearings and their surroundings clean, even if the smiling dust invisible to the naked eye gets into the bearings, can increase the wear, vibration and noise of the bearings.

2Use the installation carefully, do not allow strong stamping, do not allow direct hammering of the bearing, do not allow the transfer of pressure through the rolling body.

3Use suitable and accurate installation tools, use special tools where possible and strongly avoid the use of cloth and short fibres and the like.

4To prevent rusting of bearings, when picking up bearings directly by hand, fully wash away the sweat on your hands and coat them with high quality mineral oil before operating them, paying particular attention to rust prevention in the rainy season and summer.